In today's digital age, electronics are everywhere—from smartphones and laptops to sensitive sensors and medical equipment. With this growing demand comes the need for reliable, safe, and cost-effective packaging solutions. That’s where custom electronic packaging steps in.

Whether you're a manufacturer, distributor, or reseller, understanding how custom electronic boxes protect your products and support your business goals is key. In this article, we'll break down everything you need to know about custom electronic packaging boxes, especially if you're sourcing through electronic packaging wholesale channels in the USA.

Why Electronic Packaging Matters

Electronic devices are delicate. Static discharge, moisture, and mechanical shocks can damage them long before they reach the end-user. According to a report by the Electrostatic Discharge Association (ESDA), ESD (electrostatic discharge) causes more than $5 billion in product losses annually.

That’s why the packaging isn’t just a box—it’s part of the product’s safety system.

What Is Custom Electronic Packaging?

Custom electronic packaging refers to boxes designed specifically to protect and store electronic products. These boxes go beyond standard packaging—they include features such as:

- ESD protection

- Cushioning inserts

- Moisture barriers

- Tamper-evident seals

- Tailored dimensions to fit the product perfectly

Unlike generic packaging, custom electronic packaging boxes are built to match the shape, weight, and sensitivity of your products.

Benefits of Custom Electronic Boxes for Manufacturers and Retailers

Choosing custom electronic boxes offers several advantages, especially in high-stakes industries like consumer electronics, medical devices, and automotive tech.

Enhanced Product Safety

Custom packaging reduces movement inside the box and minimizes damage from external forces. Boxes can be designed with foam inserts, corrugated layers, or even antistatic coatings.

Improved Brand Value

Even though the focus here isn't on style, custom packaging allows for clean, informative labeling. It helps logistics staff identify contents quickly, and gives customers confidence in your professionalism.

Streamlined Logistics

Boxes that fit your products precisely reduce wasted space, which means lower shipping costs and more efficient warehouse storage.

The Role of Electronic Packaging Wholesale in the Supply Chain

Sourcing from an electronic packaging wholesale supplier in the USA is often the most cost-effective strategy. Wholesale packaging providers typically offer:

- Lower unit costs for bulk orders

- Customization services

- Faster lead times

- Support for regulatory compliance (e.g., RoHS, REACH)

According to IBISWorld, the packaging industry in the U.S. is worth over $84 billion, with electronic packaging forming a significant segment, especially in high-tech manufacturing regions like California, Texas, and New York.

Key Materials Used in Custom Electronic Packaging Boxes

Understanding material options is critical. The materials used for custom electronic packaging must offer protection, flexibility, and compliance with industry standards.

Common Materials Include

- Corrugated cardboard: Ideal for cost-effective, lightweight packaging.

- Plastic clamshells: Offer visibility and better protection for small electronics.

- ESD-safe foam: Essential for sensitive components.

- Rigid setup boxes: Used for premium electronics or instruments.

How to Choose the Right Custom Electronic Box for Your Product

Choosing the right packaging depends on the product’s size, weight, and fragility. Here’s a simple checklist:

Criteria | Recommendation |

Size | Go for a snug fit to reduce movement |

Sensitivity | Use ESD-safe or foam-lined materials |

Quantity | Opt for electronic packaging wholesale for cost savings |

Shipping destination | Ensure durability for long-distance transit |

Branding needs | Include printed labels or instructions |

Compliance and Safety Standards in the USA

Electronics packaging must comply with certain standards. Some important ones include:

- RoHS (Restriction of Hazardous Substances)

- REACH (Registration, Evaluation, Authorization and Restriction of Chemicals)

- ASTM D4169 for packaging performance testing

Working with a U.S.-based packaging provider helps ensure these compliance needs are met without delays or added cost.

Custom Electronic Packaging Boxes for Different Industries

Let’s look at how different sectors are using custom electronic packaging boxes:

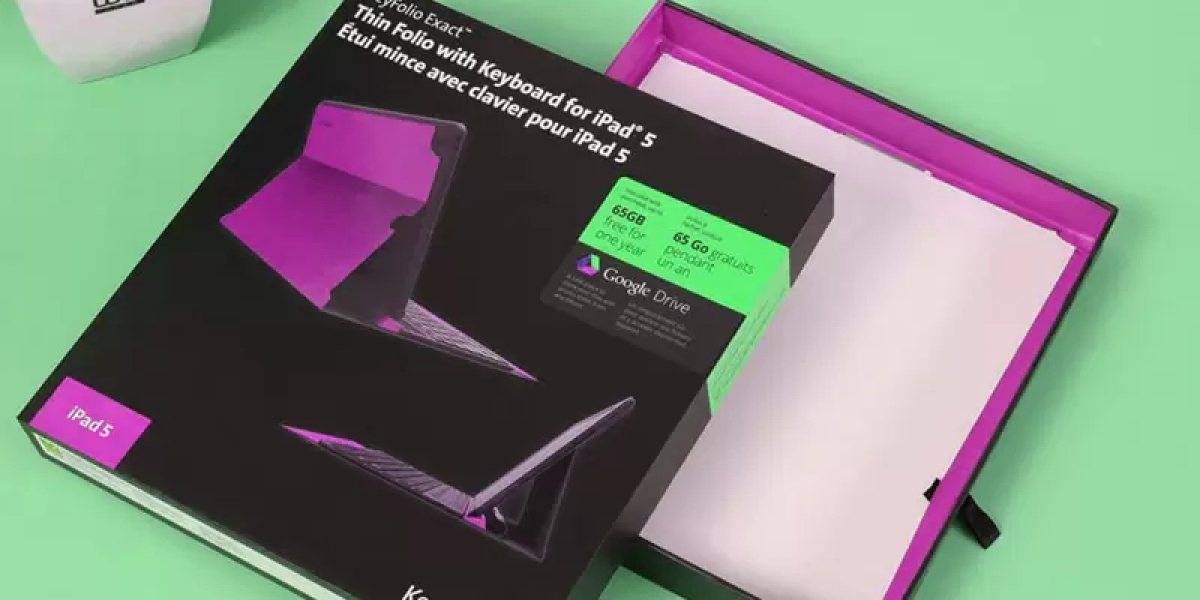

- Consumer Electronics: Smartphones, chargers, headphones—these often come in branded, retail-ready boxes with internal compartments.

- Medical Devices: ECG machines, insulin pumps, and other sensitive tools require moisture-proof, sterile packaging.

- Automotive: Sensors and chips used in modern vehicles need anti-vibration and static-safe packaging.

- Aerospace & Defense: Highly sensitive components need layered protection and detailed labeling.

Why U.S. Businesses Prefer Domestic Packaging Partners

Many companies now prioritize local partnerships for packaging needs. Here's why:

- Faster turnaround times

- Easier communication and coordination

- More control over quality

- Reduced shipping costs compared to overseas sourcing

This is especially true for companies that need custom electronic packaging in small-to-mid-sized batches with frequent updates.

Final Thoughts: The Future of Electronic Packaging

As electronic devices evolve, so will the need for smarter packaging. With trends like IoT, wearable devices, and compact smart gadgets, the demand for custom electronic packaging boxes will continue to rise.

Companies that invest in tailored, protective, and efficient packaging today will stay ahead in tomorrow’s competitive market.

If you're a business in the USA looking to scale operations and reduce risks, choosing custom electronic boxes through a trusted electronic packaging wholesale supplier is a practical next step.